BIASHARA EXCHANGE TOURS: THE BUILDING BLOCKS OF QUALITY CONSTRUCTION

An organization’s growth and overall profitability greatly relies on collaboration. This is a valuable way for enterprises to learn from each other, consolidate expertise and increase competitiveness. To expand their knowledge, enterprises can collaborate through open forums and presentations, which highlight areas of common interest for the various enterprises and allow for the exchange of ideas. This enables the firms to inform each other’s business strategies and operations for optimum utilization of the available market opportunities and trends in technology.

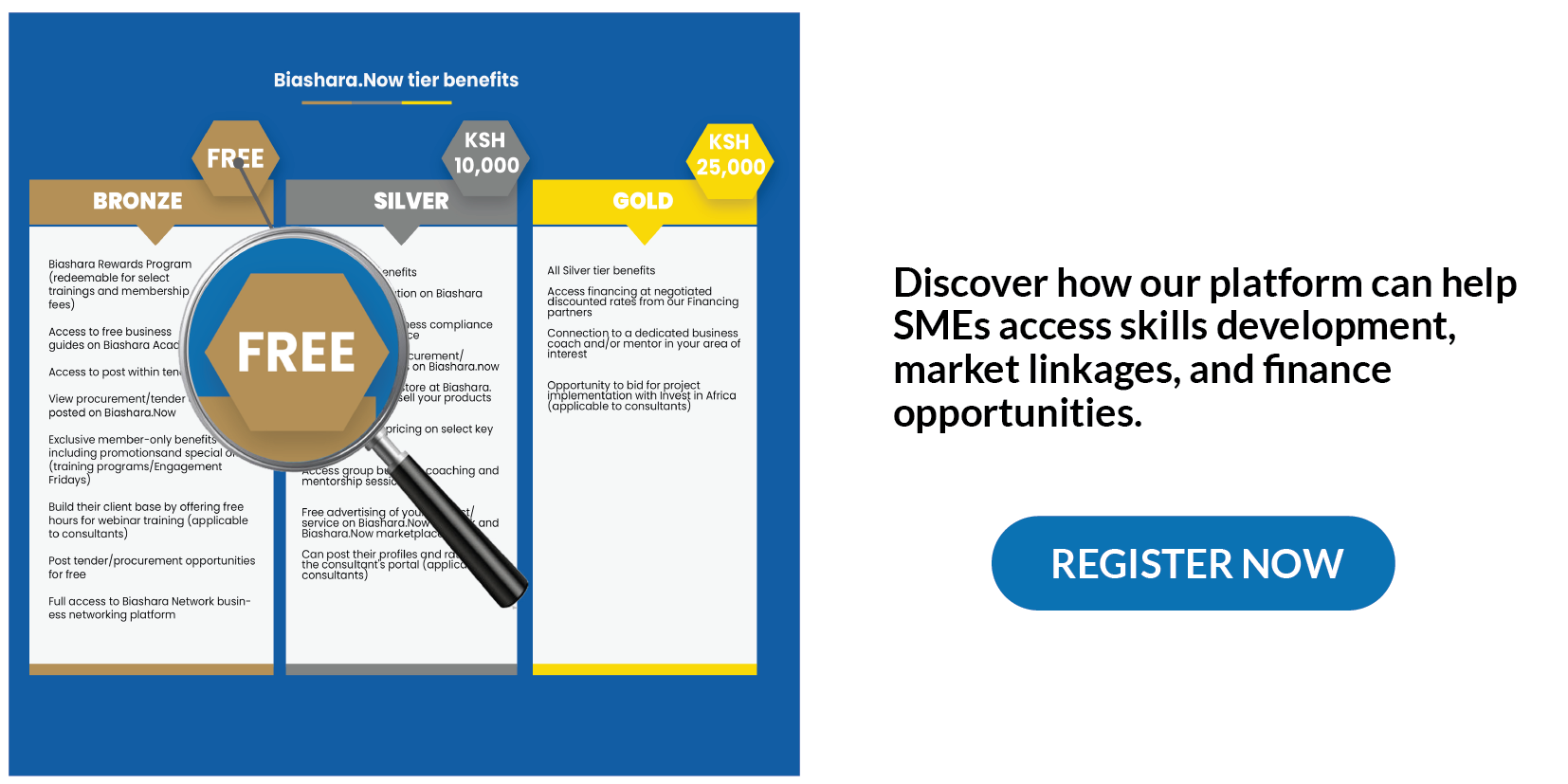

One of the key pillars of Invest in Africa is to provide access to skills for SMEs. As a result, we introduced the monthly Business Exchange Tours for SMEs registered on our online platform, Biashara.Now. These tours involve visits to a fellow Biashara Network member firm to enhance Business-to-Business linkages through the exploration of market, learning, and business knowledge exchange opportunities.

This month’s tour was to Rhombus Concrete and involved contractors and construction firms from the platform. The company manufactures and supplies premixed concrete from its main batching plant located in Nairobi. “Rhombus Concrete was founded in the year 2015 by two directors who identified an opportunity in the market to produce quality concrete,” said George Muturi, the Brand Manager, during the tour.

The tour started with a brief introduction session by Dennis Okore, the Stakeholder Engagement Manager, Invest in Africa, before the team proceeded to Rhombus Concrete. Twelve enterprises were represented in the tour, and were taken through Rhombus Concrete’s profile, to enable them to understand their strategic and operational structure. This session was handled by the Brand Manager.

The discussion included the advantages of Rhombus Concrete for example how the company provides for the need for quality concrete in constructions, which the traditional on-site mixing might not offer. Quality concrete consists of specific amounts of the constituent materials to meet quality standards. Another factor that determines quality is the time taken to supply which is determined by the distance between the project and the batching plant.

The company can deliver to projects of any size, from small short-term projects, to mega long-term projects. It currently supplies concrete only but is considering venturing into other support services in the industry, through collaboration with relevant entities.

The biggest challenge for the company has been to convince the industry that ready-mixed concrete is the way to go. This is because a section of the industry is still stuck on the cost, comparing ready mix with traditional on-site mixing. Ready-mixed concrete is cost effective because it is composed of quality materials in the right quantities.

The team also toured the batching plant to understand the processing and supply process of the premixed concrete. They learned the advantage of premixed concrete over the traditional on-site mixing and the importance of having quality inputs in the right quantities.

Most of the visitors promised to source their concrete from Rhombus Concrete, because they were assured of the quality, cost and time efficiency of the company.